Lithium-Ion

Forklift Batteries

In the material handling industry, high productivity and efficiency matters your Cost of Production. Whether you have one forklift or fifty, your equipment must have the power to deliver consistent results.

Advances in Lithium Ion technology have made Lithium forklifts more cost effective in the long-term. They require virtually no maintenance and can be charged quickly even during operator breaks.

Features Of OUR LITHIUM BATTERY

Built with the highest standards

Built with the highest standards and safety redundancies. So no need to worry about anything.

Comprehensive Battery Management System

Comprehensive Battery Management System (BMS) to protect your asset from over discharging and provide SoC control for additional performance benefits.

Suitable for all applications.

Suitable for all applications. These batteries can be changed with your existing Lead acid battery of your Forklift.

Ideal for all opportunity and fast charging applications.

Ideal for all opportunity and fast charging applications. Charge for 10 minutes and use for more than 1 hour

Virtually maintenance free.

Virtually maintenance free. No hassles like daily checks. Unit availability is very high and less chance for breakdown of unit due to battery issues.

Outstanding cycle life.

Outstanding cycle life. gives you battery life more than 8 years. This will reduce your OPEX.

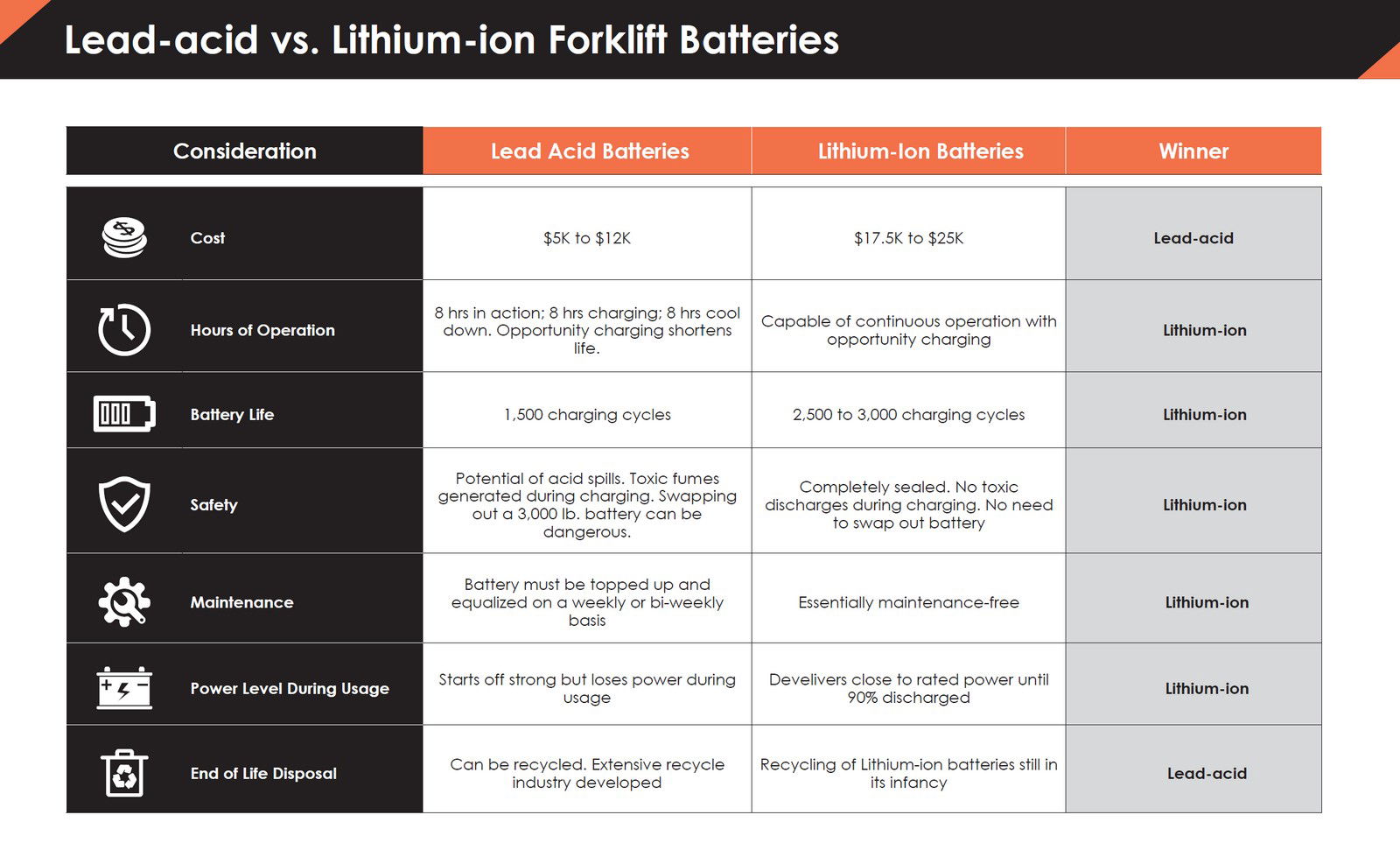

TOP 5 Benefits of Switching to Li-ion

1. Li-ion batteries are low maintenance

For a lot of people we talk to, this is the biggest difference - they love the fact that little to no maintenance is required.

Lead-acid batteries contain a balance of acid and water, and when that acid sinks to the bottom (a regular occurrence), that’s when the battery needs to be equalized. If you have these batteries, you’re probably already familiar with this process, because it happens maybe once a week. And when it does, the forklift doesn’t hold a charge nearly as well.

Also, the fluid levels need regular checking, and the temperature must be carefully regulated with cool-down periods. If not, the life of the battery will be reduced. Lithium-ion batteries, on the other hand, have no fluid, no trouble with reasonable temperature changes, and they equalize themselves.

Not only will you save money that would have otherwise been spent on regular maintenance, but you’ll also save on energy bills thanks to li-ion battery's high energy efficiency.

2. Li-ion forklifts run longer

Want to increase your team’s productivity? Li-ion batteries have longer run times, which means fewer interruptions and more spent time doing tasks that add value, rather than charging forklift batteries.

Li-ion performance does not decrease over time as the battery discharges, unlike Lead Acid batteries.

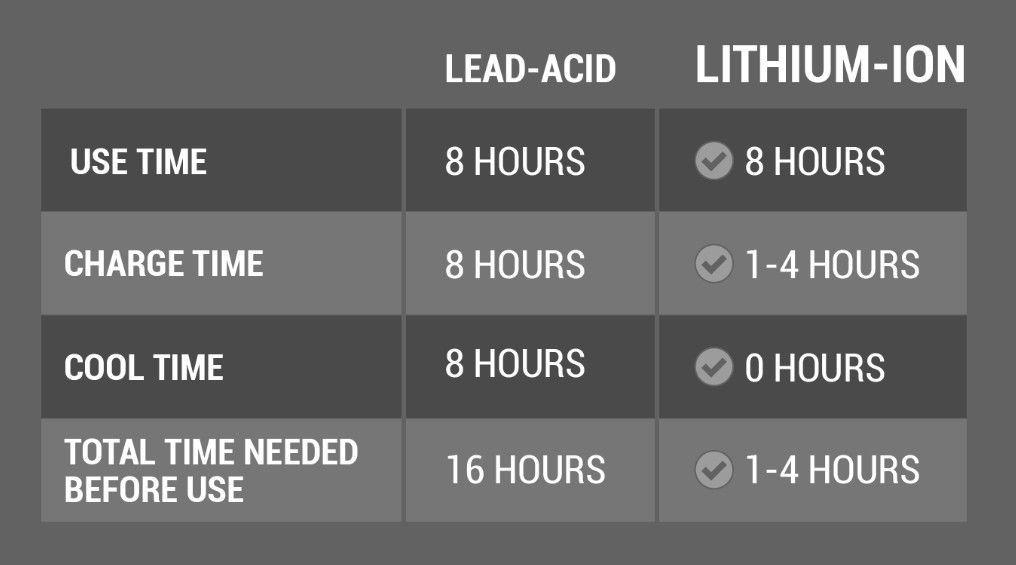

3. Li-ion forklifts are easier to charge

It’s important that operators monitor battery power on any electric model. However, for lead-acid batteries, the forklift must not be used past the 30% mark, with some manufacturers recommending that operators don’t go under 50%.

Lead-acid batteries can be used until the 20% mark before they require charging, another factor that reduces downtime and increases team productivity. Also, li-ion batteries don’t need to be swapped out as Lead Acid batteries do. Li-ion batteries charge faster and allow operators to “opportunity charge,” which is to say they can charge in-between break times since no cooldown period is required.

4. Li-ion forklifts have longer lifespans

Li-ion forklifts have longer lives than their lead-acid counterparts.

Whereas a lead-acid battery model might last 1200-1,500 cycles under normal conditions, a li-ion battery model should last between 2,500 and 3,000.

5. Li-ion forklifts are safer for the environment and people

Of course, any electric option is going to be cleaner than the fumes that come from combustion engines, so this point is especially important to businesses who care about their environmental and community impact.

Since lead-acid batteries are made of lead and sulfuric acid, they still pose a few risks that li-ion batteries don’t. If improperly handled, the fluid could spill. And charging stations must be carefully vented because, as the batteries charge, they heat up and can produce fumes.